Rock Preparation and Mineral Separation Facilities

The Department of Geology houses all the facilities necessary for cutting, crushing, pulverizing, and powdering rocks and for separating particular minerals from rocks. The products of these processes usually enjoy further analysis in one or more of our other laboratories. For more information about using these facilities please contact Sarah Penniston-Dorland.

Rock Cutting

The department contains two rock saws, a Hillquist saw with a 24-inch diameter blade and an MK tile saw with a 10-inch diameter blade.

Large rock saw

Small rock saw

Rock Crushing

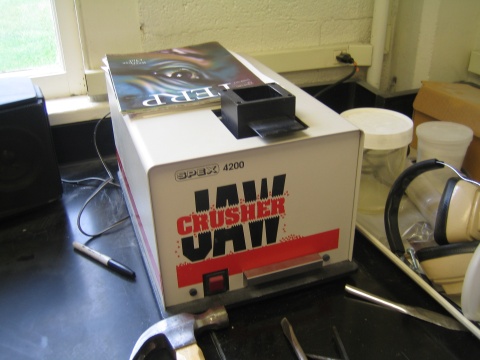

We have two electric jaw crushers, one for cobble-size pieces and the other for small pebble-size pieces. Rocks larger than cobbles must be broken prior to crushing.

Mine and Smelter Corporation large jaw crusher

SPEX 4200 small jaw crusher

We also have two stainless steel mortars and pestles for hand-powered crushing and pulverizing.

Large stainless steel mortar and pestle

Small stainless steel mortar and pestle

Rock Pulverizing

For samples with too much volume to pulverize by hand using a mortar and pestle we use a Bico/Braun disc grinder, which sits in a dust-evacuating housing.

Disc grinder

Rock Powdering

For powdering large samples we use this SPEX 8515 enclosed shatterbox. We have sample containers lined with alumina, tungsten carbide, and agate.

Large shatterbox

We usually powder smaller samples using either this small shatterbox or a mortar and pestle made of alumina or agate.

SPEX 8000M small shatterbox

Alumina mortar and pestle

Mineral Separation

The first stage in mineral separation is a density separation using water as a medium. For samples with large volumes we use a Wilfley table, and for samples with small volumes we use a hand pan.

Wilfley table

After the water separation, we remove strongly magnetic particles using a hand magnet. Following this step, we complete another density separation using one or more dense liquids, usually methylene iodide. Methylene iodide has a density of 3.325.

Fume hood for separation using dense liquids

After the separation using dense liquids, the minerals enjoy magnetic separation using this Frantz magnetic barrier separator.

Frantz LB-1 magnetic barrier separator

After these bulk separation techniques, the mineral of interest is ready to be picked by hand under a stereomicroscope.

Stereomicroscope for picking minerals by hand